Success Project

HYM Metal Works team works collaboratively with our customers’ design and technical experts to deliver high-quality metal projects that meet every requirement and performance expectation. Our experience enables us to offer cost-saving production strategies and input on the “manufacturability” of proposed projects so you can maximize your investment.

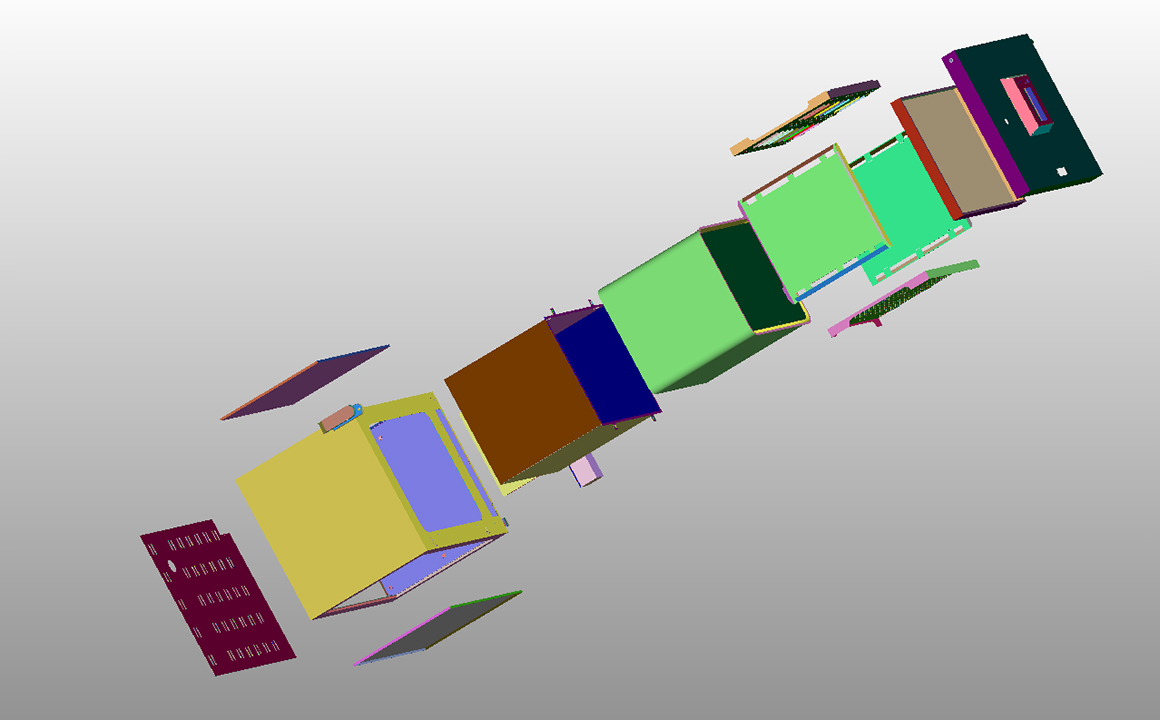

Our workflow process begins with accurate cost estimating and continues through design, programming, fabrication and assembly for four primary project types:

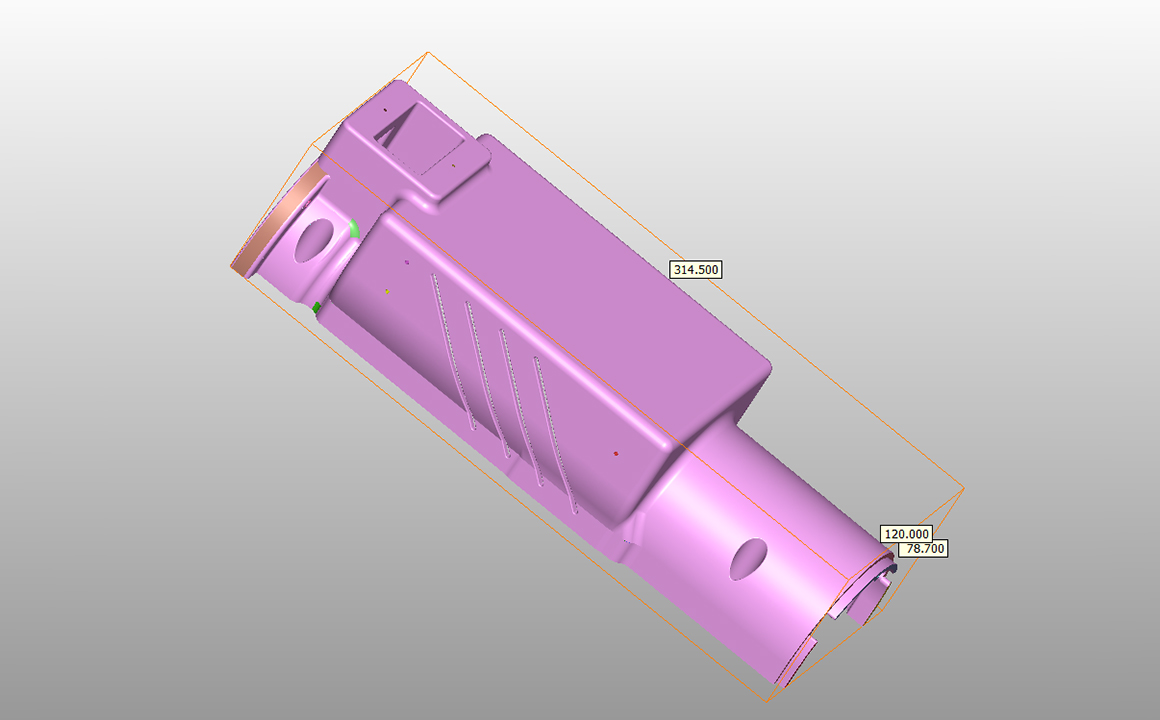

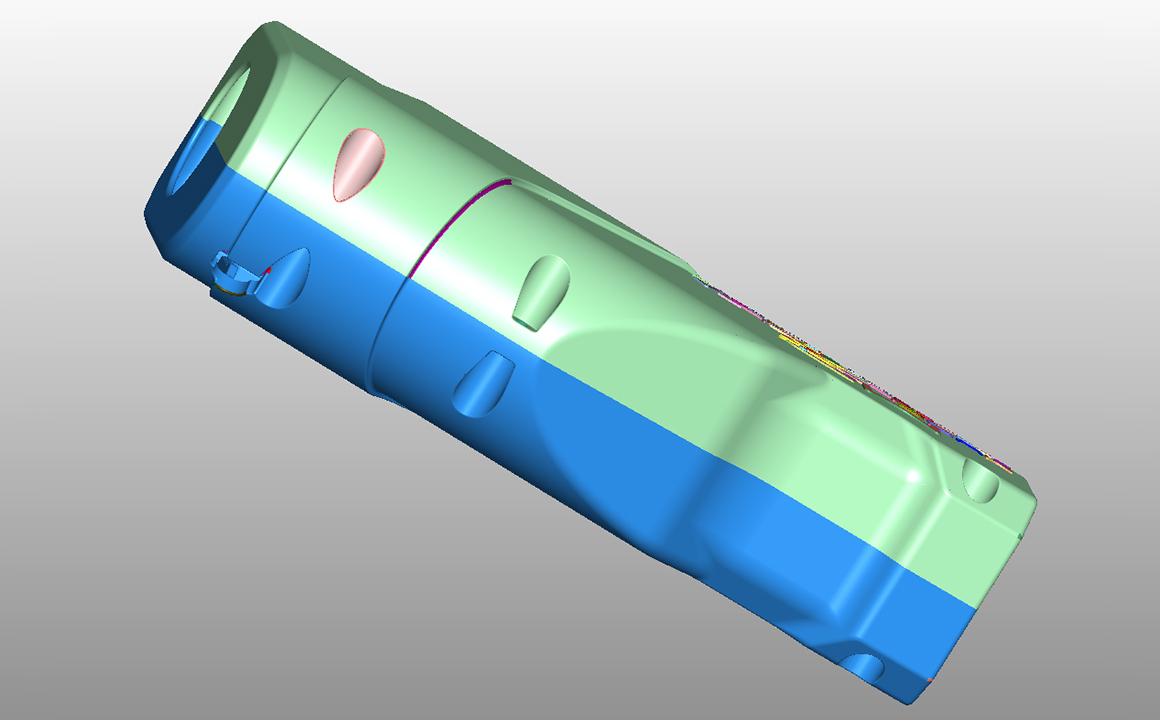

- injection molding

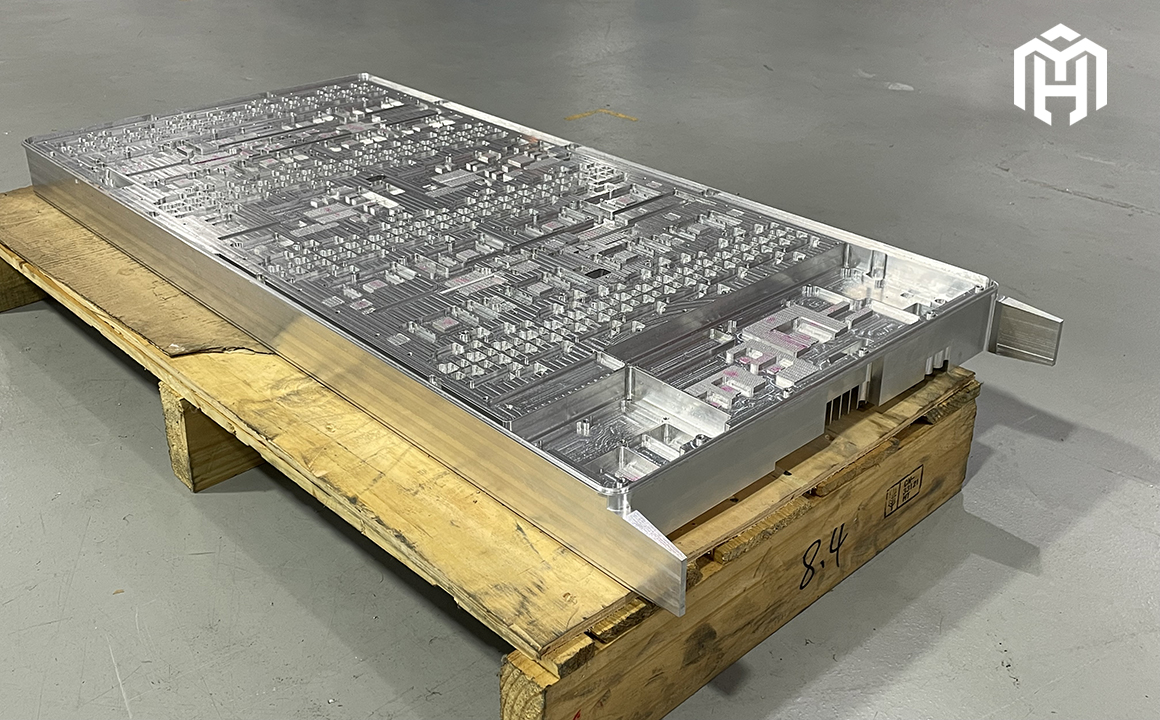

- CNC machining

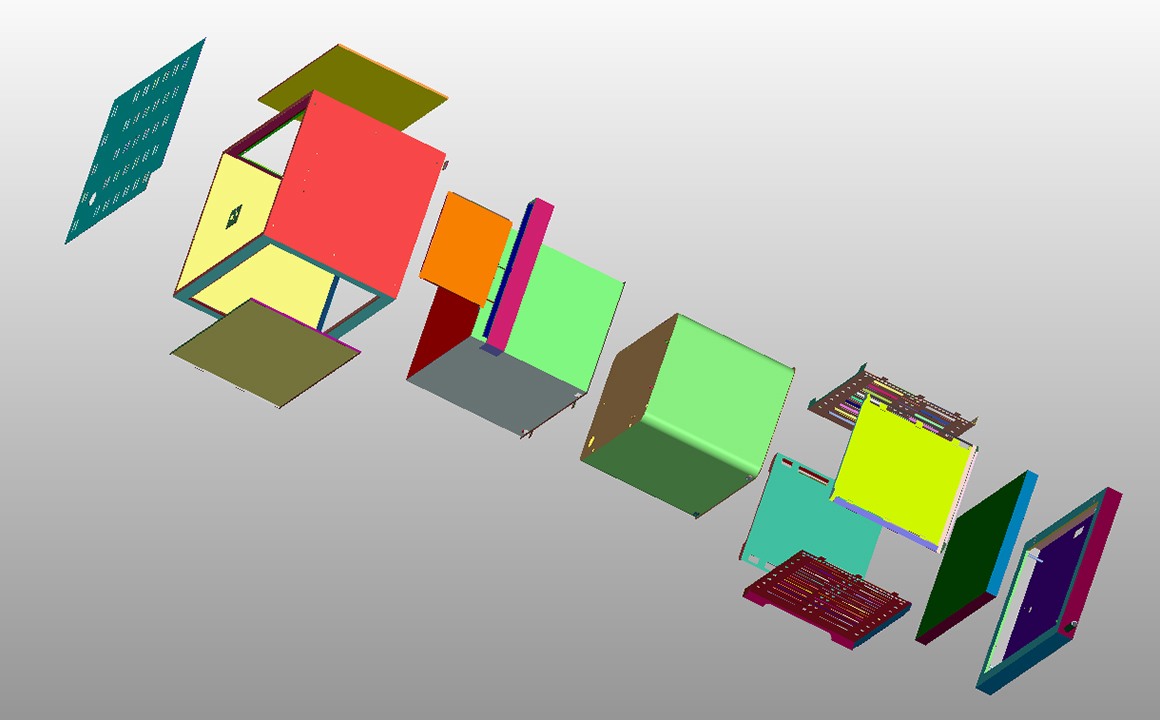

- Sheet Metal

- Medical shelf

It is important to select adequate and high-quality materials for injection molding of a specific part, and the design of the entire process is given high priority. However, it is also important to be familiar with the different cycles in the injection molding process in order to understand how to get the most out of the process. This is where the experts at HYM excel.

They have the necessary knowledge of every aspect of the injection molding process and have extensive experience in making adequate parts.

We serve OEMs and contract parts and assembly suppliers around the world. There are many ways in which HYM does business. We provide a one-stop shop, others save time with value-added ancillary services such as sawing, heat treating, plating or grinding. A fast growing part of our business is project management of precision machined metal parts

No matter how you choose to work with us, we pride ourselves on finding ways to improve your bottom line. We save time and money, from recommending better ways to source materials, to improving part designs or processes, to managing supply and inventory solutions.

Unlike many other sheet metal enclosure manufacturers, our team can be involved in any stage of your sheet metal enclosure project, including starting an entirely new product from scratch or helping you increase production by manufacturing an existing line.

We handle sheet metal enclosure fabrication for a wide range of industries and we have proven processes that work well. First, our team works with you to determine the functional and aesthetic requirements of your product.

In addition to fabricating your custom sheet metal enclosure, we will help with any machining, powder coating or other finishing, full or partial assembly, and inventory management.